As the automotive industry undergoes a seismic shift toward electric vehicles (EVs), one often-overlooked but crucial component driving this transformation is automotive die cast moulding. This technology, which involves creating metal parts by pouring molten metal into molds, is becoming increasingly essential in the production of electric vehicles. Cererea pentru matrite turnate sub presiune auto has surged in recent years, fueled by the growing need for lightweight, high-performance components in EVs.

The Role of Die Casting in Automotive Manufacturing

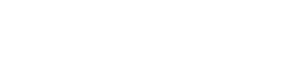

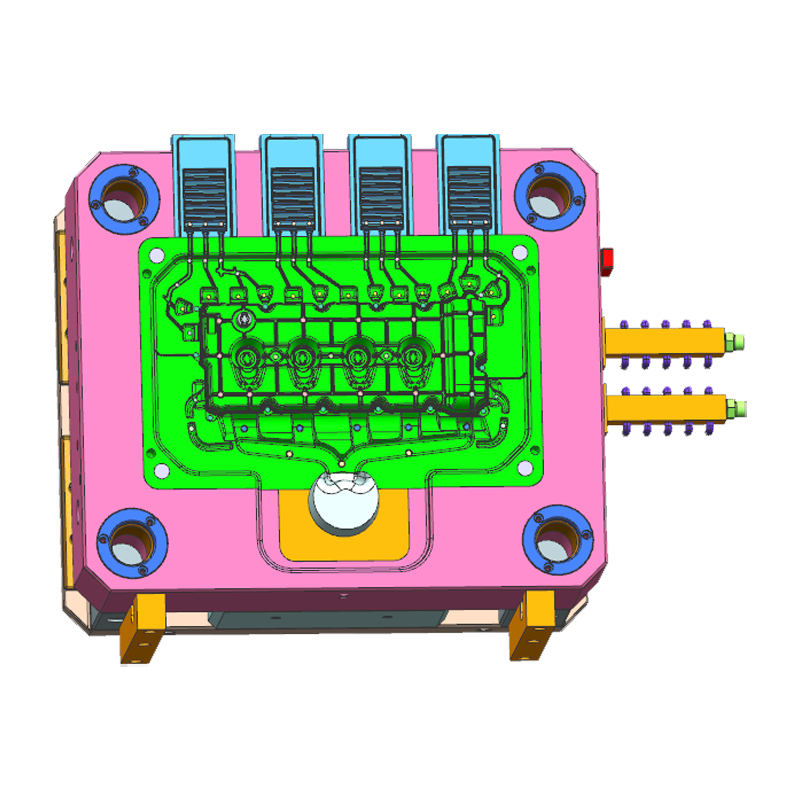

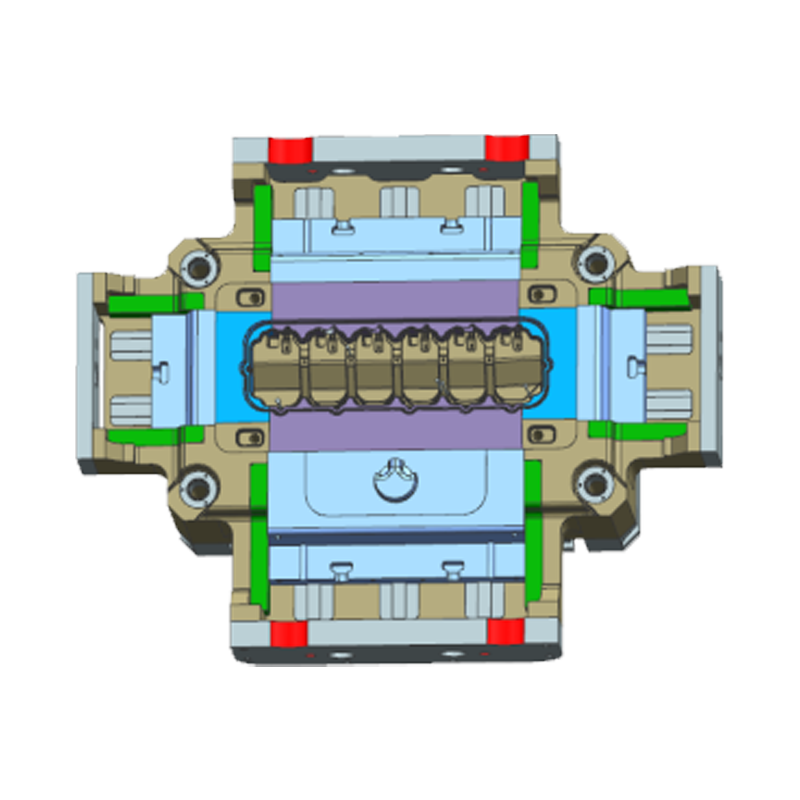

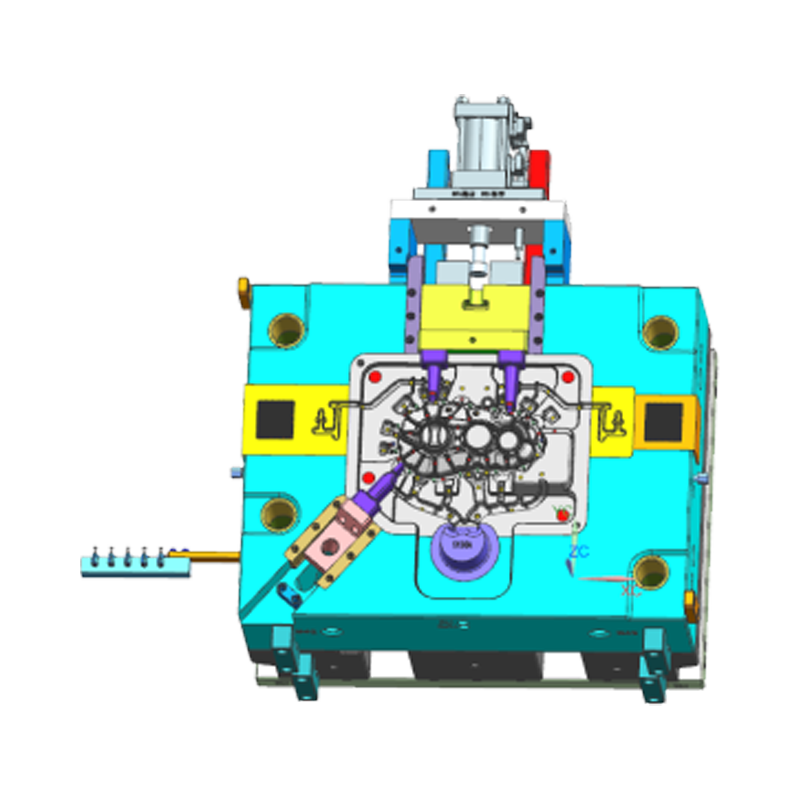

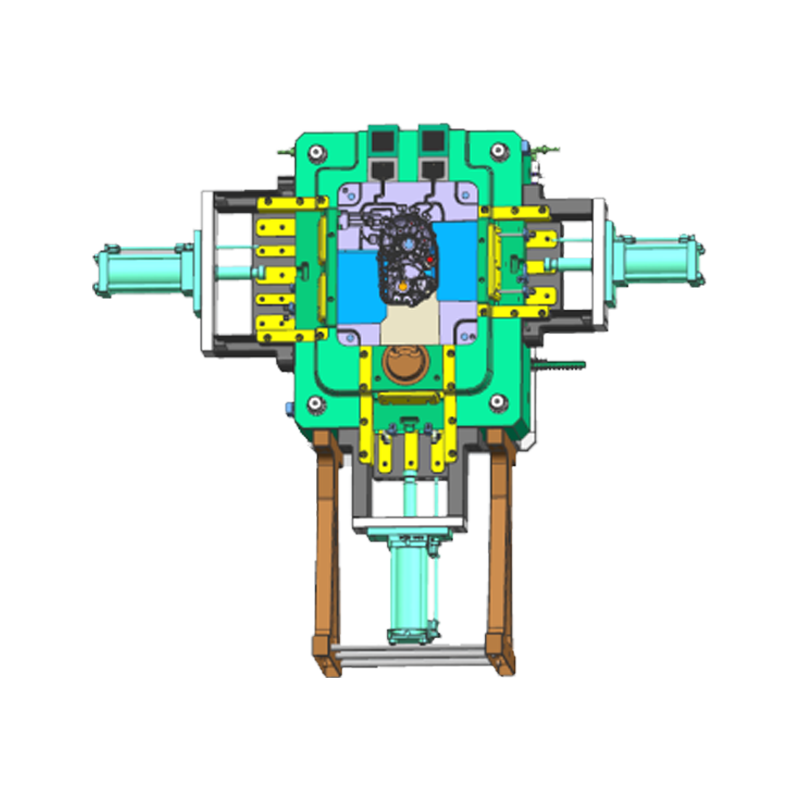

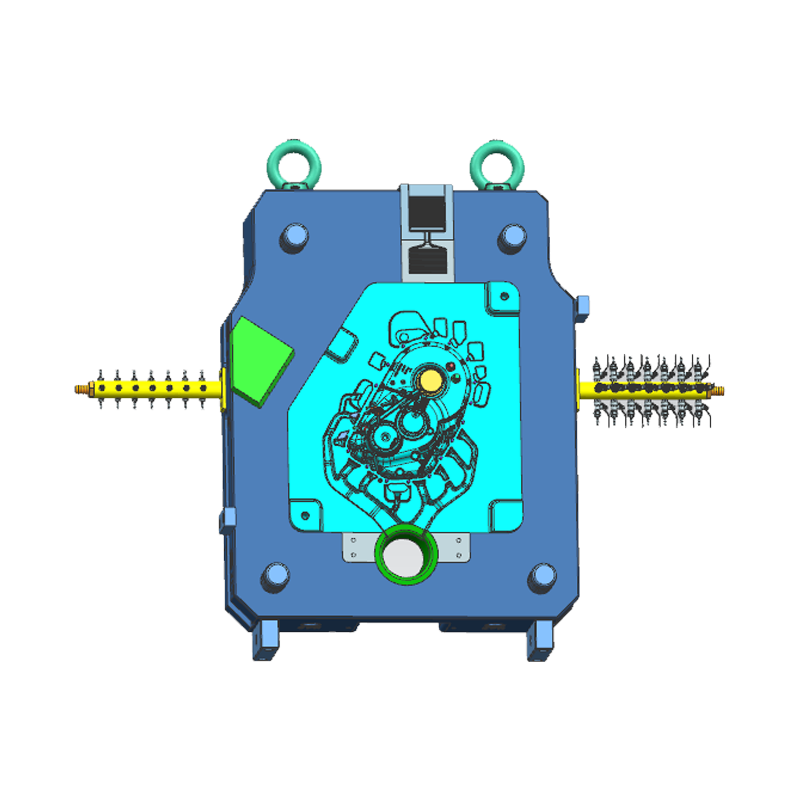

Die casting is a manufacturing process that involves injecting molten metal into a pre-shaped mold under high pressure. The result is a highly precise, durable, and complex metal part. Traditionally used in industries such as aerospace and heavy machinery, die casting has become a cornerstone of automotive manufacturing, especially with the advent of electric vehicles.

The reasons behind this shift are multifaceted, but perhaps the most significant is the drive to reduce vehicle weight. Unlike traditional internal combustion engine (ICE) vehicles, electric vehicles rely heavily on batteries for power. Batteries, especially those used in electric cars, are heavy. Therefore, any reduction in the overall weight of the vehicle is crucial for maximizing the vehicle’s range, efficiency, and performance. Die casting provides an efficient way to produce lightweight, strong, and complex parts that help achieve this goal.

Nevoia de componente ușoare în vehiculele electrice

Weight reduction is one of the biggest challenges facing the electric vehicle industry today. Un factor cheie în determinarea autonomiei și eficienței vehiculelor electrice este raportul greutate-putere. The lighter the vehicle, the less energy is required to move it, thereby extending its range and improving performance. This is especially important as consumers increasingly demand EVs with longer driving ranges.

Piesele turnate sub presiune, de obicei realizate din aliaje de aluminiu, magneziu sau zinc, sunt mult mai ușoare decât componentele tradiționale din oțel. This is particularly valuable in EV production, where reducing weight without sacrificing strength or durability is a top priority. Die casting allows for the production of parts with complex geometries and thinner walls, enabling automakers to meet stringent weight targets.

In addition to reducing the overall weight of the vehicle, die-cast parts also offer superior strength-to-weight ratios compared to many other manufacturing methods. The casting process results in dense, compact parts that retain high strength while keeping weight to a minimum. Pentru producătorii de vehicule electrice, acesta este un avantaj vital.

Aplicații specifice EV ale matrițelor turnate sub presiune

One of the most important trends driving the demand for automotive die cast moulds in the EV sector is the increasing use of die-cast aluminum in battery enclosures and structural parts. Aceste componente sunt esențiale pentru funcționarea sigură și eficientă a vehiculelor electrice. Battery enclosures, for instance, need to be lightweight yet strong enough to protect the sensitive lithium-ion cells within. Turnarea sub presiune oferă o metodă de producere a acestor piese cu mare precizie, durabilitate și greutate minimă.

The electric vehicle’s powertrain also benefits significantly from die casting. Mulți producători de vehicule electrice folosesc piese turnate sub presiune pentru componente precum carcasele motoarelor și carcasele invertorului. Aceste piese trebuie să fie rezistente la căldură, durabile și ușoare, pe care turnarea sub presiune le poate găzdui cu ușurință. The complexity of the shapes and designs required for these components—many of which are intricate and require tight tolerances—makes die casting an ideal solution.

În plus, turnarea sub presiune este din ce în ce mai utilizată în producția de elemente structurale, cum ar fi șasiu și panouri de caroserie. În vehiculele tradiționale ICE, aceste piese sunt de obicei realizate din oțel ștanțat. However, with EVs, there is a growing trend to replace steel with lightweight aluminum or magnesium die-cast parts to reduce weight and improve performance.

Avantajele cheie ale matrițelor turnate sub presiune pentru producția de vehicule electrice

Cost-eficiență

Deși turnarea sub presiune necesită o investiție inițială semnificativă în matrițe și echipamente, aceasta oferă economii semnificative de costuri pe termen lung. Capacitatea de a produce piese în volume mari cu pierderi minime face ca turnarea sub presiune să fie una dintre cele mai rentabile metode de fabricație. Additionally, because die casting allows for the production of complex parts in a single operation, it reduces the need for secondary processes, such as machining or welding, which are often required in traditional manufacturing methods.

As the demand for electric vehicles continues to rise, automakers are seeking ways to make production more efficient while keeping costs competitive. Turnarea sub presiune, cu capacitatea sa de a produce piese de înaltă calitate la scară, oferă un avantaj clar în îndeplinirea acestor obiective.

Flexibilitate de proiectare și geometrii complexe

Complexitatea tot mai mare a designului vehiculelor electrice necesită capacitatea de a produce piese cu geometrii complicate. Procesele tradiționale de fabricație, cum ar fi ștanțarea sau forjarea, se luptă adesea să îndeplinească aceste cerințe de proiectare. Die casting, on the other hand, allows for the creation of highly detailed and complex shapes that would be difficult, if not impossible, to achieve with other methods.

For example, die-cast components can incorporate intricate cooling channels, reinforcing ribs, or internal cavities, which are often necessary for EV parts like battery enclosures or powertrains. This flexibility in design also contributes to reducing the number of parts in an assembly, which further enhances the efficiency of the manufacturing process.

Finisaj și precizie îmbunătățite ale suprafeței

Turnarea sub presiune produce piese cu finisaje de suprafață netede, de înaltă calitate, reducând sau eliminând adesea nevoia de prelucrare post-producție. This is especially beneficial for electric vehicle manufacturers, where precision and aesthetics are increasingly important. The ability to produce high-quality parts with tight tolerances straight out of the mold means that automakers can reduce time and costs associated with additional processing.

Additionally, the ability to produce large quantities of uniform parts with consistent quality is a major advantage of die casting. As EV production scales up, the demand for consistent and reliable components grows, making die casting an ideal choice for mass production.

Durabilitate și beneficii pentru mediu

As sustainability becomes a key consideration in the automotive industry, die casting offers notable advantages. Procesul de turnare sub presiune este foarte eficient, producând deșeuri minime și consum de energie în comparație cu metodele tradiționale de fabricație. Aluminum, a common material used in die casting, is highly recyclable, making it an environmentally friendly option for EV production.

Furthermore, the reduction in vehicle weight not only improves the energy efficiency of electric vehicles but also reduces their environmental impact over the vehicle’s lifecycle. Lighter vehicles require less energy to operate, which directly contributes to a decrease in overall emissions.

The Future Outlook for Die Cast Moulds in EV Production

The growing demand for automotive die cast moulds in electric vehicle production is expected to continue rising in the coming years. As automakers ramp up their production of EVs to meet consumer demand and regulatory targets, die casting will play a critical role in ensuring these vehicles are cost-effective, high-performance, and sustainable.

Looking ahead, further advancements in die casting technology will continue to enhance its capabilities. Innovations in mould design, material science, and automation will likely lead to even greater efficiencies and new applications within the EV sector. Pe măsură ce producătorii se concentrează pe a face vehiculele electrice mai accesibile și mai accesibile pentru o bază mai largă de consumatori, rolul turnării sub presiune va fi esențial pentru atingerea acestor obiective.